Tiger

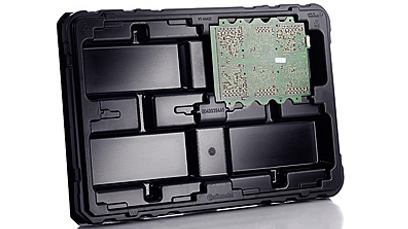

Returnable tray

Developed for the efficient and safe transport of large and heavy work pieces:

Frames optimized for gripper arms –

Interior workings as individual as

most efficient for the packing density.

The Challenge

The global logistics of work pieces for just-in-time industrial production poses a challenge for the packaging industry. Work pieces from suppliers or subsidiary factories need to be transported in sensible units across large distances and efficiently integrated in automated production chains. This requires work piece carriers that not only ensure safe transport, but also offer useful standards for automated handling at the locations. Standardized and stable forms for secure grasping by gripper arms are a must, as is anti-rotation protection and codings for integration in the digital process chain.

Solution

Thermoformed work piece carriers made of recyclable plastic from Variotech cover all of the prerequisites to meet the needs of demanding process managers. The TIGER carrier system adjusts to your processes, not the other way around. The frame offers stable pickup options for automated gripper arms and codings for recognition systems both in the form and with color and labels. The configuration of the carrier surface, developed with the help of CAD programs, produces an outstanding packing density with precisely formed and stable nests for the work pieces. Forming to the exact millimeter and advance testing with 3D printing ensures that the parts are precisely fitted for transport and yet can be easily removed from automated systems. The Tiger is designed for the transport of parts ranging in size from a few centimeters up to several meters.

Cost efficiency

made by Variotech:

Modular frame

in logistics standards –

specific interior workings

for maximum packing density

Benefits of the Tiger work piece carrier system

Circumferential groove for robotic gripper arms

Adjustable frame options for design and grip concept.

Space for barcode label

Frame options for assembly with barcode labels at Variotech.

Coding strip

Frame option for binary recognition of the work piece carrier type.

Visual and mechanical anti-rotation protection

Frame design for correct positioning of the work piece carrier with asymmetric work pieces.

Positioning cam

For setting the work piece carrier in automated production lines.

System Tiger in use –

Excellent integration in automation concepts

Euro pallet 1200 x 800

1)

Pallet lid with water drainage function (Frog)

2)

- Height-neutral lid (ca. 15 mm recess)

- Lid with no recess

- Locking lid

3)

Frames with euro pallet-compatible surface areas

- 400 x 300 mm (8 unit)

- 600 x 400 mm (4 unit)

- 800 x 600 mm (2 unit)

- 1200 x 800 mm (1 unit)

4)

Securing plate for wood or plastic pallets without safety edge

5)

Wood pallet, plastic returnable pallet or returnable pallet

ISO pallet 1200 x 1000

1)

Pallet lid with water drainage function (Frog)

2)

- Height-neutral lid (ca. 15 mm recess)

- Lid with no recess

- Locking lid

3)

Frames with euro pallet-compatible surface areas

- 400 x 300 mm (10 unit)

- 600 x 400 mm (5 unit)

- 600 x 500 mm (4 unit)

- 1200 x 1000 mm (1 unit)

4)

Securing plate for wood or plastic pallets without safety edge

5)

Wood pallet, plastic returnable pallet or returnable pallet

Half euro pallet 800 x 600

1)

Pallet lid with water drainage function (Frog)

2)

- Height-neutral lid (ca. 15 mm recess)

- Lid with no recess

- Locking lid

3)

Frames with euro pallet-compatible surface areas

- 400 x 300 mm (4 unit)

- 600 x 400 mm (2 unit)

- 800 x 600 mm (1 unit)

4)

Securing plate for wood or plastic pallets without safety edge

5)

Wood pallet, plastic returnable pallet or returnable pallet