BIRD

One-way tray

Developed for the cost-efficient transport of work pieces:

Frames are stackable as a tray or have a collapsible design –

Interior workings as individual

as most efficient.

The Challenge

Decentralized global manufacturing in today's modern industry poses great challenges for logistics. Individual components are shipped throughout the world in containers for just-in-time assembly at their destination. Many components are delicate and need to be protected from impact and environmental factors. In the competition for the lowest possible transport costs, every gram of material and every centimeter of space count. In addition, modern manufacturing places new demands on work piece carriers: They need to integrate seamlessly in automated process chains.

Solution

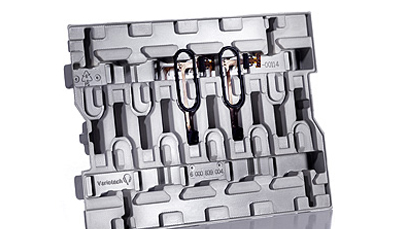

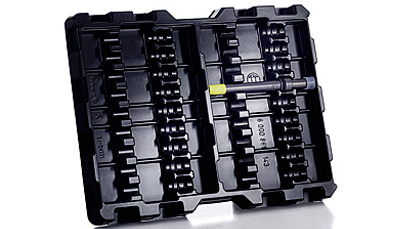

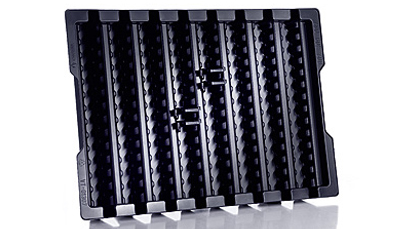

Thermoformed work piece carriers made of recyclable plastic from Variotech cover all of the prerequisites to meet the needs of cost-conscious logistics managers. The Bird carrier system offers superior packing security and cost-efficient solutions for the one-way transport of work pieces in many sizes. Unlike paper packaging or loose padding with plastic material, the components sits securely in a precisely formed nest. The collapsible version is dustproof and, thanks to its clever form, it is also stackable. The self-supporting stackable tray version makes it possible to efficiently transport multiple work pieces with minimal weight in a minimal space. The configuration of the carrier surface, developed with the help of CAD programs, produces an outstanding packing density with precisely formed and stable nests for the work pieces. Forming to the exact millimeter and advance testing with 3D printing ensures that the parts are precisely fitted. Every Bird work piece carrier is perfectly recyclable thanks to the purity of the plastic variety.

Cost efficiency

made by variotech:

maximum and secure packing density –

minimum need for material and space

Benefits of the Bird work piece carrier system

Minimum material expense, maximum security

Plastic thermoforming makes it possible to develop sturdy packaging with low material expense.

Equipped for automated handling

The work piece carrier system can be adjusted to fit existing process chains for automatic loading and unloading.

Stackable and self-supporting

As an intermediate layer, rotary stacking, in a container or cardboard box.

Collapsible packaging that is sturdy and dustproof

Sealable collapsible packaging protects components from dirt and moisture.

Highly recyclable

Plastics in classified, pure varieties ensure that they can be recycled anywhere in the world.